Call us 8:00am - 6:00pm

(0120) 2352950

E-mail us

info@jbjindia.com

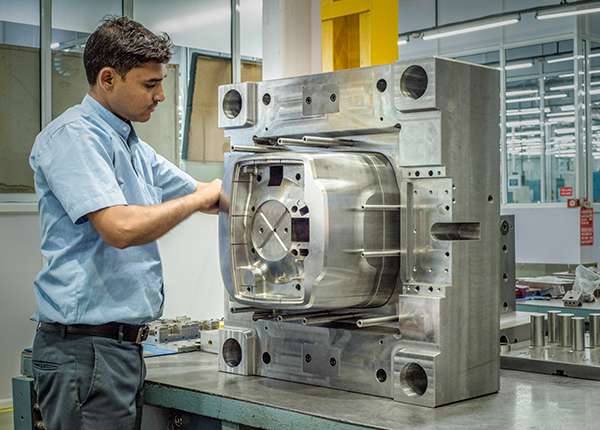

Best in class technologies for machining metal are used on our floor. Makino and Haas for milling, Charmilles for spark erosion, Sodick for wire erosion, Okamoto for grinding.

All machining processes are done under our roof as a general practice to keep quality of machining under our control and to ensure steels are not compromised.

Only the best and globally accepted mould steels, standard parts and hot runners are used.

Experienced toolmakers use years of experience and knowledge to creatively and intelligently assemble high precision and long lasting performance moulds.

Cutting edge inspection technologies, such as Mahr, Zeiss and Mitutoyo are effectively implemented to ensure the highest precision.

Project managers, assisted by our ERP softwares, work to closely monitor and deliver moulds to customers on time.

Part validation, PPAP documentation, packaging design, logistics support and complete services for smooth Start of Production are available to customers.